| Journal of Food Bioactives, ISSN 2637-8752 print, 2637-8779 online |

| Journal website www.isnff-jfb.com |

Original Research

Volume 24, December 2023, pages 46-54

Effects of ultra-fine micronization on the structure, rheological and functional properties of dietary fiber from Laminaria japonica

Jingzhang Genga, b, Jinhui Wuc, Huiying Wangc, Yanfei Liuc, Bin Duc, *, Yuedong Yangc

aShaanxi University of Technology, Shaanxi Province Key Laboratory of Bio-resources, QinLing-Bashan Mountains Bioresources Comprehensive Development C. I. C., Qinba State Key Laboratory of biological resources and ecological environment..1 East 1st ring road, Hanzhong 723000, Shaanxi, PR China

bSchool of Life Science and Technology, Xi’an Jiaotong University, Shaanxi Nutrition and Health Engineering Research Center, Xianning West Road, Xi’an 710049, Shaanxi, PR China

cHebei Key Laboratoryy of Natural Products Activity Components and Function, Hebei Normal University of Science and Technology, Qinhuangdao, Hebei 066004, PR China

*Corresponding author: Hebei Key Laboratoryy of Natural Products Activity Components and Function, Hebei Normal University of Science and Technology, Qinhuangdao, Hebei 066004, PR China. Tel: +86-0335-8077682; E-mail: bindufood@aliyun.com

DOI: 10.31665/JFB.2023.18363

Received: June 26, 2023

Revised received & accepted: October 18, 2023

| Abstract | ▴Top |

Laminaria japonica is known to be a rich source of dietary fiber (DF). The DF in L. japonica was extracted by combined enzymatic and chemical method in this study. The effect of ultra-fine pulverization on structural and functional properties of DF fractions was also investigated. The results displayed that the molecular weight of DF was 2.22 × 107 Da. After ultra-fine grinding, the viscosity of soluble dietary fiber (SDF) suspension increased from 4.65 ± 0.08 to 6.89 ± 0.24 mPa·s. In addition, ultra-fine grinding significantly reduced the particle size of DF with higher insoluble dietary fiber (IDF) yields. L. japonica IDF exhibited significant enhancement on absorption capacities of nitrite ion absorption, cholesterol and glucose, which could be utilized as potential ingredients in several DF intensified foods. This work could provide understanding into the influence of micronization on the structure-function relationship of food materials rich in dietary fiber.

Keywords: Laminaria japonica; Dietary fiber; Enzymatic and chemical method; Ultra-fine grinding; Particle size; Textural properties

| 1. Introduction | ▴Top |

Laminaria japonica, a type of flat leaf-shaped long-striped algae, belongs to cold-water marine vegetables (Cai et al., 2000). L. japonica is cultured in a large area in the coastal areas of China, and the annual production is increasing in recent years (Nie et al., 2022; Chen et al., 2017). The annual production of china reached 1.7424 million tons in 2021 (Nie et al., 2022). It is provided with high nutritional value, which is not only rich in vitamins and minerals, but also high in dietary fiber (DF) and crude protein (Chen et al., 2019; Cheng et al., 2020; Wang et al., 2022). Therefore, L. japonica is widely utilized in functional foods, herbal medicine (e.g. treatment of constipation), or cosmetics (Chang et al., 2010). L. japonica was reported to exert several healthy benefits, such as regulating blood sugar and blood lipids, enhancing human insulin resistance, and lowering blood pressure (Fang et al., 2015; Duan et al., 2019). Among those functional ingredients, DF played one of the most important roles.

DF has several benefits for human health (Swennen et al., 2006; Slavin, 2013; He et al., 2022). It is generally believed that DF is very meaningful for nutrition and health, such as DFs from mushroom (Wong and Peter, 2005), grape pomace (Zhu et al., 2014), hull-less barley (Du et al., 2014), ginseng residue (Hua et al., 2019), asparagus (Gao et al., 2020) and pea (Wang et al., 2021). The key functionalities of DF, including water holding capacity, cation binding and sorption of bile acids, play pivotal roles in the treatment of numerous diet-related diseases, e.g. obesity, high cholesterol, atherosclerosis, diabetes mellitus (Wang et al., 2021; Lin et al., 2021) and colon cancer (Dziedzic et al., 2012). DF may create a viscous layer on the surface of intestinal villi, which reduce absorption of cholesterol (Lu et al., 2022) . Moreover, nitrite scavenging capacity of DF may have been associated with protecting in connection with gastric cancer (Moller et al., 1988). It has been reported that the application of DFs from apple and oat influenced the rheological and textural properties of waxy potato starch (Adamczyk et al., 2020; Niu et al., 2014). However, the average global intake of DF is still significantly below the recommended daily intake levels (Approximately 30 grams for adult males and approximately 25 grams for adult females) (Phillips, 2013). It is of practical importance to supplement DF using emerging food processing technologies from various plant/food origins.

Ultra-fine grinding technology (incl. ball-milling, and airflow pulverization) is a recently developed food processing that is applied to produce food ingredient powders with enhanced functionalities (Zhu et al., 2014; Wu et al., 2012; Gao et al., 2020; Hong et al., 2020; Zhang et al., 2020; Zhao et al., 2009). Compared with conventional grinding methods, ultra-fine powder undertakes good physical properties such as reduced surface tension and steric hindrance effects (Zhu et al., 2012; Ting et al., 2014). At present, the ultra-fine grinding processing has been adopted in various food products, such as ginger extracts (Zhu et al., 2015), Astragalus membranaceus powder (Zhao et al., 2010) , and food byproducts (e.g. wheat bran (Zhu et al., 2010), fish bone powder (Wu et al., 2012), wine grape pomace (Zhu et al., 2014), and soybean residue (Li et al., 2020), wheat beta-glucan (Kurek et al., 2016), and some antioxidants (Rosa et al., 2013).

In the present study, using L. japonica as raw material, DF was extracted by combined enzymatic and chemical method. Ultra-fine grinding was carried out to study the structure and function of DF, and compared with DF under regular grinding. The influence of ultra-fine grinding on structural (e.g. particle size distribution, molecular weight, Fourier transform infrared spectrum) and functional properties (e.g. textural properties, viscosity, and absorption capacities of nitrite ion absorption, cholesterol & glucose) were investigated. The possible structure-function relationship of DF from L. japonica was developed. DF before and after ultra-fine grinding was proposed, and possible application was discussed.

| 2. Materials and methods | ▴Top |

2.1. Materials and chemicals

Fresh L. japonica was acquired in the local market (Qinhuangdao, Hebei, China), and was dried viaoven at 40 °C 24 hours before uses. Neutral protease and cellulase were bought from Heshibi Technology Co., Ltd. (Yinchuan, Ningxia, China). Zinc acetate was purchased from Fengyang Chemical Reagent Technology Co., Ltd. (Tianjin, China). Lead nitrate and copper sulfate were offered from Kaitong Chemical Reagent Co., Ltd. (Tianjin, China). All other chemicals were of analytical grade, which were bought from Fengyang Chemical Reagent Technology Co., Ltd. (Tianjin, China).

2.2. Preparation of L. Japonica DF

After drying, L. japonica was ground to powder with a regular laboratory mill (FZ102, Tianjin Taisite Co. Ltd., Tianjin, China). DF was prepared from L. Japonica powder with regular grinding using the method published by Ma et al. (Ma et al., 2022) with slight modifications. Twenty gram dried L. japonica powder was suspended in 400 mL Milli-Q water, and one gram cellulase (Yinchuan, Ningxia, China, 400 U/mg) and one gram protease (Yinchuan, Ningxia, China, 50 U/mg) solution was added for enzymatic hydrolysis at 50 °C. The digested samples were centrifuged at 4,000 rpm for 20 min at room temperature, and the supernatant and precipitate was collected, respectively. The supernatant was mixed with 4-time volume of ethanol at 4 °C, and the precipitate was collected. After drying at 103 °C, the samples were ground into powder using a regular laboratory mill (FZ102, Tianjin Taisite Co. Ltd., Tianjin, China).

2.3. Preparation of ultra-fine grinding L. Japonica DF

Ultra-fine grinding of insoluble dietary fiber (IDF), soluble dietary fiber (SDF), total dietary fiber (TDF) was carried out based on our previously published paper (Zhu et al., 2014). Briefly, the samples were further pulverized by mini-type airflow pulverization instrument (QLM-80K, Shangyu City Heli Powder Engineering Co., Ltd., Zhejiang, China), respectively. The working pressure was set at 70 MPa and the working frequency was set at 40 Hz. Ultra-fine ground L. japonica powder and ultra-fine ground IDF were sealed with aluminum foil and kept in a desiccator for further study.

2.4. Determination of DF contents

TDF, SDF, and IDF contents were measured using enzymatic gravimetric procedure in accordance with the Association of Official Analytical Chemists method (AOAC,1996;AOAC,2000).

2.5. Particle size determination of L.Japonica DF

The particle size distribution of ultra-fine ground IDF was measured using the procedure described by Zhu et al (Zhu et al., 2014). Briefly, a laser diffraction particle size analyzer (LA-920, Horiba Limited, Japan) was applied to determine the particle size distribution of ultra-fine ground IDF, SDF, TDF. The ground powder was suspended in ethanol directly in the measuring cell (small volume unit module) and the suspensions were analyzed when the obscuration was between 70% and 80%.

2.6. The structure of L. Japonica DF

2.6.1. Measurement of molecular weight (MW)

L. Japonica SDF was determined using the procedure described by one reference (Du et al., 2017). L. Japonica SDF was characterized for molecular weight using Agilent 1100 series high performance liquid chromatography (HPLC) system (Agilent Technologies Palo AHO, CA, U.S.A.) equipped with a TOSOHTSK-GELG 3000 SWXL column (7.8 mm × 30 cm, 10 µm; TOSOH Corp., Tokyo, Japan) and a refractive index detector. The sample of 20 µL (1 mg/mL) was injected in the system with column temperature of 35 °C, and the flow rate of 0.5 mL/min using 0.05 mol/L phosphate buffer (pH 6.7) containing 0.05% NaN3 as the mobile phase. The average molecular weight was calculated by the calibration curve obtained using various standard dextrans (0.738, 5.8, 11.22, 21.37, 41.8, 110, 118.6, 318 and 813.5 kDa).

2.6.2. Fourier transform infrared (FT-IR) spectrum

The FT-IR spectrum of the DF was measured through the procedure described by Du et al (Du et al., 2022) .

2.7. Textural properties and viscosity of L. Japonica IDF

2.7.1. Textural properties measurement

The DF prepared by enzymatic hydrolysis combined with chemical method and ultra-fine pulverization was placed at room temperature and cut into blocks of 25 mm. The breaking strength and concavity degree of DF were measured using TA.XT PlusC texture analyzer (Stable Micro System Company). The strength of the fracture can reflect the hardness of the DF. The spherical probe was used to pierce the sample to 20 mm. Tests were performed in triplicated, and gel property (N.mm) was calculated as follows:

2.7.2. Viscosity measurement

SDF (1.0 g) from L. japonica was added to 19 mL of pH 7.2 phosphate buffer, shaking for 1 h, and placed at room temperature for 12 h. The concentration of SDF samples were adjusted in deionized water at 10 g/L and the measurement was performed at 25 °C. The viscosity of the solution was determined by a LV DV-II + Pro viscometer (Brookfield Company, Stoughton, MA, U.S.A.).

2.8. Analysis of functional properties of L. japonica DF

2.8.1. Nitrite ion absorption capacity (NIAC) of L. Japonica IDF

NIAC of L. Japonica IDF was measured following zhu et al (Zhu et al., 2014). Briefly, a portion of dried L. Japonica IDF (1.0 g) was mixed with 100 mL 1 mol/L NaNO2 solution in a 250 mL conical flask. The pH was adjusted to 7.0, and the mixture was incubated at 37 °C for 75 min with continuous mild agitation. The residual concentration of nitrite ion was measured. NIAC was expressed as follows:

2.8.2. Cation-exchange capacity (CEC) of L.Japonica IDF

The cation-exchange capacity was measured by a regular titration method, based on a published paper (Cheng et al., 2010). IDF from L. Japonica was accurately weighed (0.5 g) and placed in a 150 mL of conical flask, and then mixed with 100 mL of NaCl solution with a concentration of 5% and magnetically stirred for 5 min. Sodium hydroxide solution (0.5 mL, 0.1 mol/L) was used to titrate (877 Titrino plus Automatic Potentiometric Titrator, Metrohm AG, Ionenstrasse, Switzerland) each time and used pH meter to monitor the pH value.

2.8.3. Cholesterol absorption capacity (CAC) of L. Japonica IDF

The CAC of L. Japonica IDF was conducted by referring a published paper (Hu and Huang., 2003) with slight minor modifications. The standard solutions (0, 250, 500, 750, 1,000, 1,250, 15,000 μg/mL) were made by diluting cholesterol stock solution with glacial acetic acid and iron vitriol chromogenic agent. IDF (1.0 g) was placed in a 250 mL flask, and 50 g of diluting egg yolk (1:10, w/w, with Milli-Q water) was added; pH was adjusted to 7.0, and then IDF was shook for 2 h at 37 °C. The sample was centrifuged at 5,000 rpm for 20 min, and supernatant (1 mL) was mixed with 3 mL glacial acetic acid, and 2 mL iron vitriol Fe-V chromogenic agent. The sample was kept at room temperature for 20 min and the absorbance was measured at 570 nm.

2.8.4. Pb, Zn, Cu ions adsorption capacity of L.Japonica IDF

The adsorption capacity of IDF from L.Japonica was determined by an Inductively coupled plasma - optical emission spectrometry (ICP-OES) method (Nawirska, 2005). IDF from L. Japonica were suspended in a 50 mL solution containing 30.0 μg/L Pb, Cu, and Zn ions, respectively, with concentration at 1, 3, 5 mg/mL. The pH was adjusted to 7.0, and the sample was shaken for 6 h at 37 °C. The sample was centrifuged at 5,000 rpm for 20 min, and the supernatant was collected for measurement.

2.8.5. Glucose absorption capacity of L.Japonica DF

The adsorption capacity of IDF or SDF to glucose was measured according to the method of Rios et al (Rios et al., 2020). Briefly, 0.1 g ultra-fine DF powder was mixed with 20 mL glucose solution (50 mmol), cultured at 37 °C for 2 h, and then centrifuged at 4,000 rpm for 20 min. The concentration of glucose in the supernatant by DNS colorimetric method, and perform blank test with distilled water. The calculation method of glucose adsorption capacity refers to the calculation of glucose adsorption capacity of soybean dregs IDF.

2.9. Statistical analysis

All results in this work were expressed as mean ± standard deviation of three replicates. Data in triplicate were analyzed by one-way analysis of variance using SPSS 11.5 software (SPSS Inc, USA).

| 3. Results and discussion | ▴Top |

3.1. L. japonica DF fraction and yield

The particle size reduction of the DF exhibited a remarkable influence on content and composition. As shown in Table 1, the TDF, IDF and SDF contents (wt%) of the L. japonica were decreased after ultra-fine grinding. The results confirmed the previous study that the DF content of the asparagus pomace increased with increasing granularity (Gao et al., 2020), and the yield enhancement was around 40%, 44%, and 17% for TDF, IDF and SDF, respectively, based on current investigationa. The ratio of IDF to SDF increased from 1.37 to 1.70 after ultra-fine grinding, indicating IDF mainly contributed to the yield enhancement and might play more important role on the functionalities.

Click to view | Table 1. Effect of ultra-fine grinding on the yield of L. japonica DF* |

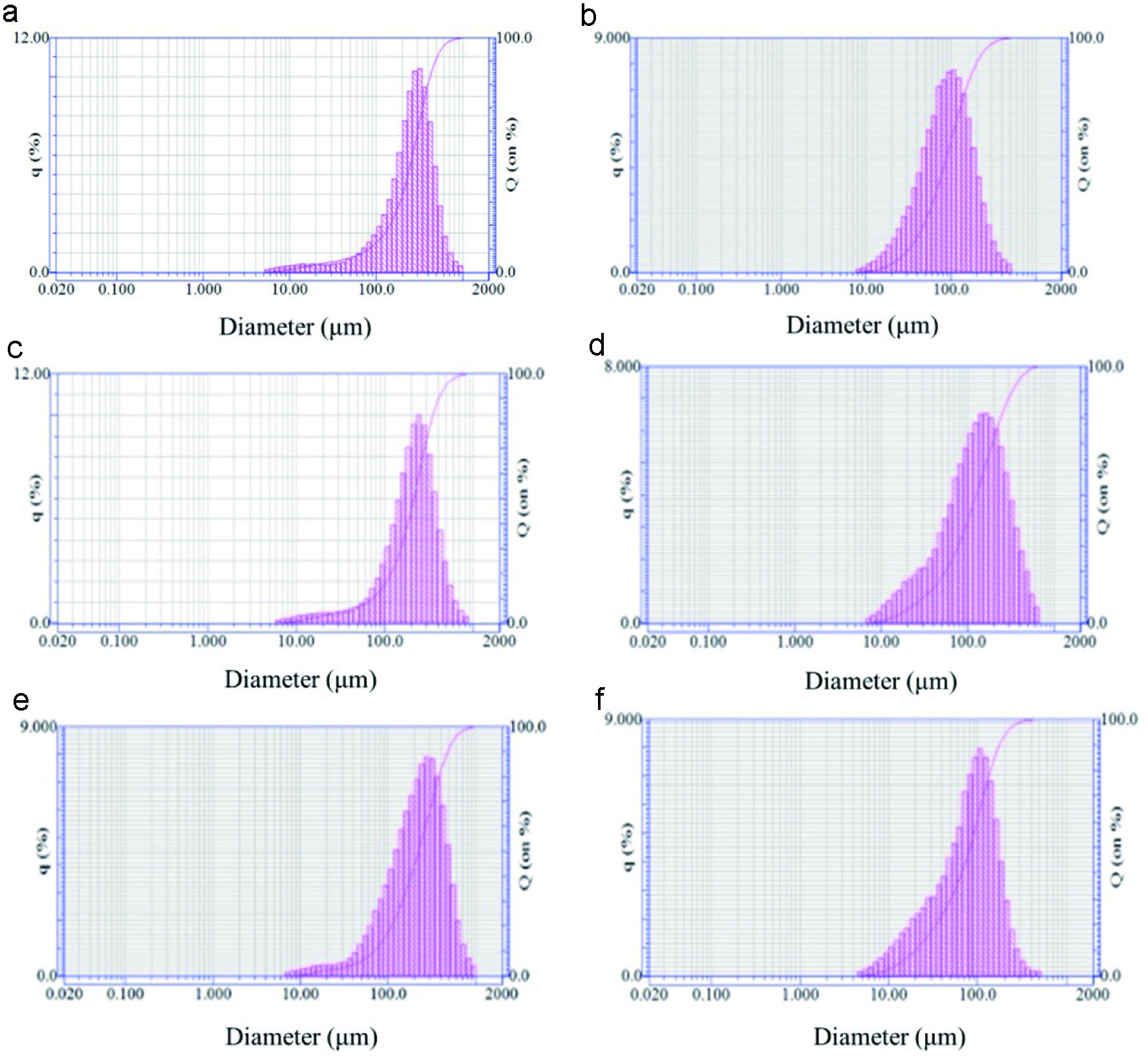

3.2. Particle size of ultra-fine grinding L. japonica DF

As listed in Table 2, before ultra-fine grinding the median diameter (d50) of the samples of TDF, IDF, and SDF were reduced after ultra-fine grinding, and distribution patterns are presented in Fig. 1. All the distribution patterns are Gaussian distribution. The results revealed that ultra-fine grinding could reduce the sizes of the IDF particles to a small size. Zhu (Zhu et al., 2010) reported a smaller particle size of ultra-fine wheat bran DF using multi-dimensional swing high-energy nano-ball-milling, and the mean particle size of the ultra-fine DF was 343.5 nm. It is worth to note that the different results in the reported studies might be related with the different DF origins, such as mushroom or wheat (Du et al., 2022). In this study, the trend of particle size decrease of SDF was similar to IDF.

Click to view | Table 2. Effect of ultra-fine grinding on particle size in L. japonica DF* |

Click for large image | Figure 1. The putative schematic diagram of structure, rheological and functional properties of dietary fiber from L. japonica. |

These results were in accordance with previous studies in which bulbs of Fritillaria unibracteata Hsiao et K.C. Hsia powder after ultra-fine grinding displayed smaller particle size, bulk density and span value compared to those of fine powder (Li et al., 2019).

3.3. The structural characterization of L. japonica DF

The MW of SDF from L. japonica was 2.22 × 107 Da. As shown in Fig. S1, the single peak in HPLC analysis suggested that the DF after ultra-fine grinding is homogeneous (Fig. S1). Another study indicated that the weight average molar mass (Mw) of Pleurotuseryngii polysaccharide was 8.372 × 106 Da (Ting et al., 2014). The difference of Mw could be caused by the different species, extraction temperature, extraction time, or fractionation methodology.

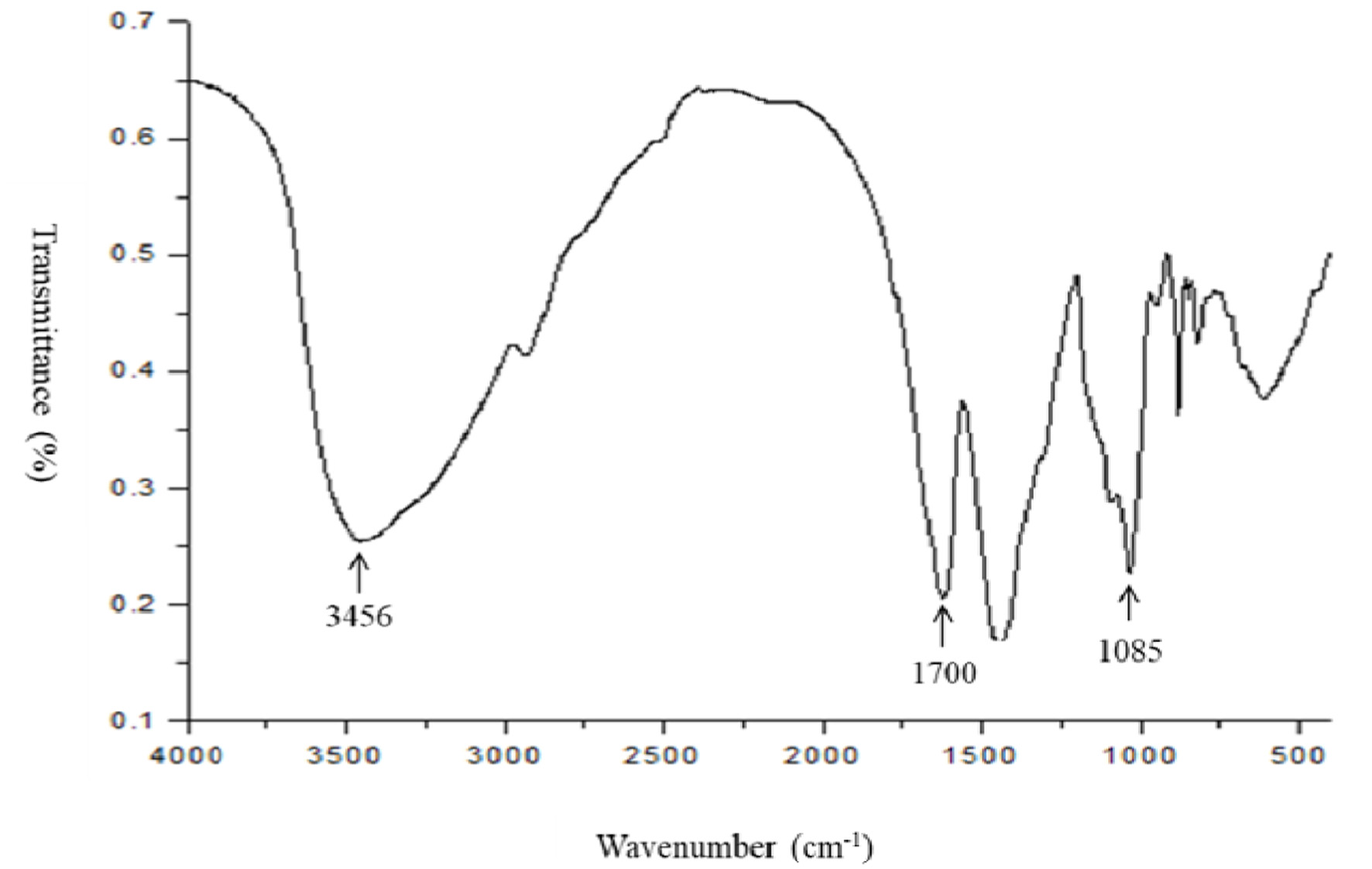

The FT-IR spectrum of L.japonica IDF fractions after ultra-fine grinding is shown in Fig. 3. A strong band at 3,456 cm−1 represented hydroxyl stretching vibration of the polysaccharides. The high absorbency ranged of 1,085 cm−1 was the characteristic absorption peak of polysaccharides. A strong stretching vibration at around 1,700 cm−1 (C=O) indicated the presence of carboxyl groups (Luo et al., 2020).

Click for large image | Figure 2. Particle size distribution of L. japonica DF before and after ultra-fine grinding. (a) IDF before ultra-fine grinding; (b) IDF after ultra-fine grinding; (c) SDF before ultra-fine grinding; (d) SDF after ultra-fine grinding; (e) TDF before ultra-fine grinding; (f) TDF after ultra-fine grinding). |

3.4. Gel property and viscosity of L. japonica DF

The granularity reduction of L. japonica DF had a remarkable effect on their gel property and viscosity. As shown in Table 3, through ultra-fine grinding, the gel property in L. japonica SDF changed from 17.39 ± 0.07 to 9.316 ± 0.03 N·mm. The reason could be that ultra-fine grinding disperses DF particles and reduces agglomerates sizes. Meanwhile, the viscosity in L. japonica SDF increased from 4.65 ± 0.08 to 6.89 ± 0.24 mPa·s after ultra-fine grinding. These findings were comparable with the previous study: high pressure homogenisation broke up the cells, which resulted in cell fragments suspended in an alginate rich liquid phase increasing the viscosity more than ten times (Saioa et al., 2015). The gelling properties can be affected by different factors, such as concentration and micronization method.

Click to view | Table 3. Effect of ultra-fine grinding on gel property, viscosity, nitrite ion absorption capacity (NIAC), cation-exchange capacity (CEC), cholesterol absorption capacity (CAC), Pb2+, Cu2+ and Zn2+ in L. japonica SDF* |

3.5. Functional properties of L. japonica DF

The granularity reduction of the IDF of the L. japonica had a remarkable effect on their functionalities as indicated in Table3. All of the nitrite ion absorption capacity (NIAC), cation-exchange capacity (CEC), and cholesterol absorption capacity (CAC) of L.japonica IDF increased after ultra-fine grinding. These results are in accordance with previous studies in which the NIAC of Qingke flour DF was increased using fine grinding (Du et al., 2014). The possible reason could be that ultra-fine grinding efficiently increased the surface area of IDF.

The CEC of L. japonica IDF was increased from 0.26 mmol/g to 0.38 mmol/g. The side-chains of DF contained hydroxyl and carboxyl groups, and this unique chemical structure may function as acid cation exchange resins, which can be reversibly exchanged with a cation (Gao et al., 2015). Moreover, the CAC was also increased from 3.54 mg/g to 7.34 mg/g using ultra-fine grinding. Similarly, Ou (Ou et al., 2005) used an in vitro study to test cholesterol in eggs after liquid fermentation, and the CAC was 14.0 ± 0.7 mg/g.

DF can help reduce blood cholesterol and control blood glucose. The possible reasons could be that DF absorbs water and generates a gel, which decreases digestion. DF exhibited a significant gel-forming capacity by absorbing and binding higher bound water at surfaces (Salem et al., 2020; Salem et al., 2021). The gel also enhanced satiation, which postponed the emptying of stomach and help control body weight (Wang et al., 2021).

It has been reported that acute experimental variations in glycemia accelerate gastric emptying (Aigner et al., 2021). Gastric emptying is delayed in 30–50% of patients with longstanding diabetes mellitus (Horowitz et al., 1996). An increased intake of dietary fiber, which resulting in increased satiation, is useful for the relief of gastric emptying and the treatment of diabetes mellitus.

It is well known that trace amounts of heavy metal have negative impacts on brain, kidney, and reproductive system at low levels throughout the food chains (Gao et al., 2015), and Pb ion is the most abundant heavy metal in cereals and vegetables. As indicated in Table 3, the effect of ultra-fine grinding on Pb2+, Cu2+ and Zn2+ of L.japonica IDF were evaluated. As indicated in Table 3, Pb, Cu, Zn ion adsorption capacity was significantly increased (p < 0.05) after ultra-fine grinding, and lower ion concentrations were observed in the supernatant. Some correlated studies on different plant origins were also reported: DF from pomegranate peel (Ozcan et al., 2011) and wheat bran (Ou et al., 1999) could decline the toxicities of lead at a low concentration. However, Peng et al. (Peng et al., 2020) reported that there was no significant difference between the green tea and fine-grind green tea powder on Cu2+ and Zn2+ adsorption. and further comparison of fine grinding on DF from various origins is recommended.

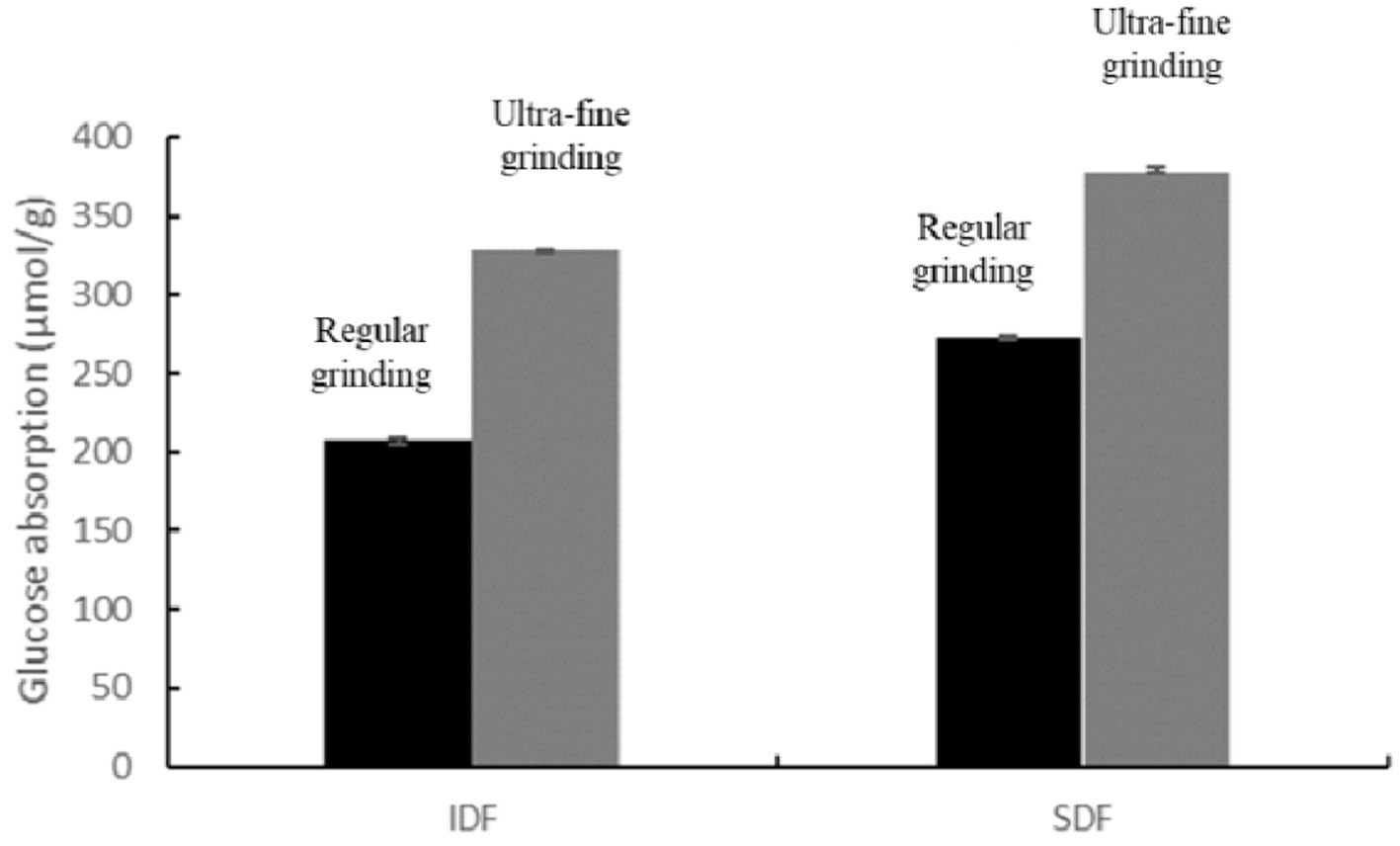

As shown in Fig. 4, glucose absorption capacity of L.japonica IDF increased from 207.1 to 327.6 μmol/g, and SDF increased from 272.4 to 377.8 μmol/g after ultra-fine grinding. Ultra-fine grinding could increase the particle surface area, and DF with larger surface area had remarkable glucose absorption capacity. This is equivalent to the results obtained by Wang et al. (Wang et al., 2021), which demonstrated ultra-fine grinded pea DF had a notable influence on decreasing blood glucose and glycosylated hemoglobin in diabetes mellitus mice, and increasing the tolerance to glucose. Compared with the raw IDF, a grinding-treated sample (10.48 µm) yielded a higher glucose adsorption, which may assist its function in intestines (Ma et al., 2016). Moreover, enoki mushroom IDF exerted stronger glucose adsorption capacity and the ability to regulate fat digestion (Yang et al., 2021).

Click for large image | Figure 3. FT-IR spectrum of IDF after ultra-fine grinding in the range of 4,000–500 cm−1. |

After ultra-fine grinding, the particle size of DF decreased, but the primary structure remained unchanged. The gel property reduced due to smaller agglomerates sizes of DF, and the viscosity increased, which might be caused by cell fragments suspended in the liquid phase. The NIAC of IDF increased due to more porous structure of IDF (Gao et al., 2020). The side-chains of L. japonica DF contained hydroxyl and carboxyl groups, and this may function as acid cation exchange resin which can be reversibly exchanged with a cation (Gao et al., 2015). Pb, Zn, Cu ions adsorption capacity decreased due to heavy metal ions on the surface of DF diffuse slowly into the more micropores of ultra-fine grinding (Liu et al., 2006). The glucose absorption capacity of L. japonica IDF and SDF (Fig. 4) increased as the particle size decreased (Wang et al., 2022; Gao et al., 2020). Moreover, ultra-fine grinding IDF had more particles per unit weight and could thus entrap more glucose molecules within the fiber.

Click for large image | Figure 4. Glucose absorption capacity of L. japonica IDF and SDF. |

| 4. Conclusions | ▴Top |

The ultra-fine grinding could significantly reduce the particle size of L. japonica DF to micronized-scale, yielding DF with higher IDF contents. The single peak in HPLC elution profile suggested that the DF after ultra-fine grinding was homogeneous with MW of 2.22 × 107 Da. Ultra-fine grinding processed L. japonica IDF had many remarkable functional characteristics, with improved capacities of nitrite ion absorption, cholesterol and glucose absorption. The favorable functional activities of the L. japonica DF confirmed their potential as potential ingredients in several functional foods. The ultra-fine grinding process could be a beneficial processing technology in DF fortification strategy to produce commercial functional foods.

| Supplementary material | ▴Top |

Figure S1. GPC of DF from L. japonica.

This research was funded by The Natural Science Foundation of Hebei Province (C2019407092) and Hebei province’s key research and development program (216Z3201G), Open Project Program of Shaanxi Key Laboratory of Bio-resources(SLGPT2019KF03-04).

Conflict of interest

The authors declare no conflict of interest.

| References | ▴Top |