| Journal of Food Bioactives, ISSN 2637-8752 print, 2637-8779 online |

| Journal website www.isnff-jfb.com |

Mini-Review

Volume 24, December 2023, pages 6-12

Do date codes cause food waste? Smart packaging might tackle the problem

Abul Hossain

Department of Biochemistry, Memorial University of Newfoundland, St. John’s, NL A1C 5S7, Canada. E-mail: abulh@mun.ca

DOI: 10.31665/JFB.2023.18359

Received: December 23, 2023

Revised received & accepted: December 28, 2023

| Abstract | ▴Top |

Food waste is a multifaceted problem that occurs across various sectors of the food supply chain, causing significant repercussions on the environment, food security, and both global and regional/national economies. One of the most common reasons for food waste is the misunderstanding of food dating (e.g., best-before date), leading to the throwing away of food more frequently. Consumers tend to discard food products as they approach the best-before date due to potential health and safety concerns. Many argue that the diversity of date labels employed by food manufacturers contributes to confusion among consumers regarding both food quality and safety, thus causing food waste. Removing/ supplementing date codes requires the adoption of alternative methods to maintain the freshness and safety of food. Recent advancements in smart packaging have the potential to extend the shelf life and maintain the safety of products equipped with a range of features, which allow the monitoring of the condition of packaged products and provide information. Given the global concern over food waste, this review emphasizes the implementation of smart (active and intelligent) packaging in order to supplement the date labels and assist consumers in reducing their waste and maintain the integrity of its bioactive components.

Keywords: Date code; Best-before date; Food waste; Active packaging; Intelligent packaging; Retention of bioactives

| 1. Introduction | ▴Top |

Food loss and waste throughout the food supply chain are a major challenge in the global food production. Over 30% of the food produced for consumption is lost or wasted at various stages of the supply chain. Annually, a staggering 1.3 billion tones of the global food supply, valued at over $1 trillion, is wasted, lost, and disposed of in landfills. Regrettably, a considerable portion of food waste is preventable, and recovering just half of what is currently lost or wasted could potentially feed an entire population (Ganeson et al., 2023). Food waste encompasses consumer-level wastage, both edible and inedible, occurring during the distribution and consumption stages. In particular, date coding plays an important role in food waste since numerous wordings on date labels and misconceptions about the interpretation of expiry dates directly result in a higher frequency of discarding food. The Codex Alimentarius suggests the implementation of two types of dates on food products: one associated with food health safety and the other with product quality (Zielińska et al., 2020). For example, the “best-before date” signifies the period during which a properly stored and unopened food product is expected to retain its taste, freshness, nutritional value, and other attributes as claimed by the manufacturer. Nonetheless, for perishable food items that are susceptible to rapid microbiological spoilage and may pose a direct threat to human health shortly after production, the “best-before” date is substituted with the “use-by” date. Apart from this, other date coding such as sell-by, best-if-used-by, fresh-by, prepared-on, manufactured-on, and freeze-by dates are also used by different manufacturers, which causes consumer confusion. In particular, “best-before date” is often misunderstood with “use-by” date, resulting in most consumers disposing of food primarily because they perceive it to be spoiled or believe that it has lost its taste and freshness. There is evidence indicating that consumers tend to waste food products as the date on the label approaches (open date label), driven by perceived concerns about food safety (Wilson et al., 2017).

Recent advancements in smart (intelligent and active) packaging and smart labels have the potential to extend the shelf life of products, retain the integrity of its bioactive components, and offer consumers actionable information regarding the optimal time to consume food products. Smart packaging is a novel approach to addressing food waste, and especially in an era marked by reduced processing, decreased use of additives, and growing demands on the supply chain. Smart packaging technology integrates active packaging with the latest technological advancements to bolster the packaging’s capacity to prevent food loss. Additionally, it aims to provide consumers with more information and awareness to deter both intentional and non-intentional food waste (Ganeson et al., 2023). Notably, active packaging uses active ingredients to modify the packaging materials in order to preserve or enhance the safety, sensory, and quality aspects of the food. However, intelligent packaging is defined as packaging capable of perceiving a situation through an external or internal indicator, offering insights into the quality, history, and safety of the food (Ahmed et al., 2022). As a result, these technologies have the potential to supplement date labels and assist consumers in reducing their waste. Therefore, this review discusses the effects of date coding on food waste generation and how smart packaging can be a prominent way to tackle this issue. The relevant data were collected from Scopus, PubMed, ScienceDirect, and Google after searching various keywords, mainly “date coding/labeling”, “best-before date”, “use-by date”, “food waste”, “smart packaging”, “active packaging” and “intelligent packaging”, among others.

| 2. History of food product dating | ▴Top |

Date labels mainly emerged in the post-World War II decades, coinciding with a shift in American consumer behavior from local grocery stores and farms to supermarkets. Before that, during the 1930s, manufacturers introduced a second category of food date labels, specifically targeting grocers rather than consumers. Referred to as “sell-by” labels, these were intended for internal store use, featuring a coded system that provided grocery store employees with a designated date for selling products. The primary purpose of including dates was to enhance sales by providing evidence of a commitment to quality rather than any other motive. Initially, manufacturers incorporated date codes on cans and packages to assist grocers in managing their inventory effectively. These codes, decipherable only by retail staff using a key, were indecipherable to customers. In response to increasing consumer demands for information on food quality in the 1970s, dates were prominently added to labels as a safety precaution, aiming to protect customers from purchasing and consuming potentially unsafe food. Nevertheless, these labels continued to be restricted to certain perishable items, such as dairy and baked goods. In 1973, the Food and Drug Administration (FDA) revamped its regulations on food labeling by introducing an optional “Nutrition Information” label. This decision was influenced by the positive outcomes of various supermarket trials involving nutrition labeling. While some state legislatures enacted laws mandating these consumer-focused labels on food packaging, attempts to establish nationwide standards generally continued to rely on voluntary measures (Frohlich, 2023; Mullen, 2023).

| 3. Types of date codes | ▴Top |

Usually, two kinds of product dating may appear on a product label. “Open dating” involves a calendar date applied by manufacturers or retailers, providing consumers with an estimate of the optimal period for the product’s quality and helping stores determine how long to display it for sale. On the other hand, “closed dating” is a code, typically comprising letters and/or numbers, used by the manufacturer to find the time and date of production. Various types of open dating labels exist, varying depending on the product. The most prevalent ones include best-before, packaged-on, and expiration dates. According to the Canadian Food Inspection Agency (CFIA) the “best-before date” indicates the duration during which a properly stored and unopened food product will maintain its taste, freshness, nutritional value, and other attributes claimed by the manufacturer. If the unopened product has been appropriately handled, it is expected to retain its quality until the best-before date. Nevertheless, it is crucial to understand that these dates do not ensure product safety; instead, they offer insights into the freshness and potential shelf-life. Consuming foods after the “best-before” date might still be safe, but there’s a possibility that they have experienced a decline in quality and may have lost some nutritional value. Manufacturers typically select best-before dates well in advance of the anticipated deterioration and spoilage of the food. For example, canned and frozen foods often maintain their quality for a significant period beyond the “best-before” date. It is important to emphasize that a best-before date differs from an expiration date. An “expiration date” is mandatory only for specific foods with stringent nutritional and compositional specifications that may not be met after the expiration date. Usually, expiration dates are included in formulated foods, infant formulas, and nutritional supplements, among others. On the other hand, “packaged-on dates” are akin to best-before dates but are applied to foods packaged at retail with a durable life of 90 days or less, depending on the legislation. Together, the packaged-on date and durable life information provide insights into the expected duration during which an unopened product will maintain its freshness and quality. Products with an expected shelf life exceeding 90 days are typically not mandated to have a best-before date or storage information, as they are generally regarded as shelf-stable. This may include dry foods such as pasta, canned foods, and foods sold in a frozen state. Apart from this, use-by, sell-by, prepared-on, manufactured-on, and freeze-by dates are also used in different countries. In particular, for foods that pose health and safety concerns if consumed beyond a certain date, a “use-by” date is required to indicate the deadline by which the product should be consumed. Within reasonable limits, if a food item appears and smells as expected, it is generally considered safe to eat even after the “best-before”/“best-if-used-by” dates have passed. However, it is crucial to note that for items labeled with a “use-by” or “expiration date” dates, it is not advisable to consume them beyond that date, even if they seem to be visually and olfactorily fine. From a microbiological perspective, the “use-by” term is used for foods that are highly perishable and are thus expected to pose an immediate risk to human health after a certain period. The introduction of these date codes serves as a crucial safety measure that may become unsafe to eat (Frohlich, 2023; Mullen, 2023; USDA).

| 4. Issues with date codes and generation of food waste | ▴Top |

Confusion about date labeling contributes to food waste, and currently, there are approximately 50 different types of date codes in use in the USA without standardized regulations (Patra et al., 2022). Over 40% of food that is still suitable for consumption is needlessly thrown away due to inaccuracies in dates or confusion about their actual meaning. According to the 2020 edition of the Tetra Pak Index, 39 percent of global consumers admitted to discarding food simply because the “best-before” date had passed, even if the food did not exhibit any signs of spoilage in terms of smell or appearance (Holmquist, 2022; Mullen, 2023). For example, the Canadian food industry discarded approximately 8.79 million tones of potentially consumable food annually, as indicated by a 2022 report from Value Chain Management International (Benchetrit, 2022). Moreover, a significant number of Europeans mix up best-before dates, which indicate the recommended timeframe for optimal freshness, with expiration dates. Over 80% of confusion arises from the distinctions between use-by, best-if-used-by, and best-before date codes on food, resulting in consumers discarding fresh food. A survey conducted by the Harvard Food Law and Policy Clinic (2016) revealed that 84% of consumers consistently or occasionally dispose of food when it reaches a date printed on the label. Only 67% were aware that “best-by” dates signify a food product’s quality and freshness, with 15% incorrectly perceiving them as indicators of food safety and 12% considering them labels for storing. Wilson et al. (2017) conducted a between-subject laboratory experiment, incorporating various date labels (best-by, sell-by, fresh-by, and use-by) for different products (salad greens, ready-to-eat cereal, and yogurt) with distinct sizes and expiration dates. The aim was to assess how these date codes impact subjects’ premeditated food waste behavior or their willingness to waste (WTW). The results indicated that WTW was highest in the “use-by” coding, where the date label was potentially less ambiguous and more suggestive of food safety concerns. Conversely, WTW was lowest in the “sell-by” coding, where the date label may be more ambiguous concerning safety or quality for the consumer. Furthermore, as per The Waste and Resources Action Programme (WRAP), UK households discard 6.6 million tones of food annually that could have been consumed. Among the food waste generated by households, 41% (by weight) results from products being “not used in time,” indicating that they are thrown away due to spoilage or exceeding the date label. A portion of the food waste stems from individuals using date labels in a manner inconsistent with their intended purpose, such as employing a “best-before” date as a “disposal-date” for a product. For example, when it comes to milk, only 31% of individuals would discard milk that is one day past the best-before date, whereas nearly half (47%) would do so if it were one day past the use-by date. Regarding yogurt, over half of people (53%) would dispose of the product if it were one day past a use-by date, while only 34% would do the same for yogurt one day past a best-before date. Like the UK, in the US, approximately 30–40% of food is wasted annually, and this can be attributed in part to the numerous labeling conventions in use, such as expiration, use-by, sell-by, best-by, best-if-used-by, and so on. Additionally, the European Commission (EC) estimates that up to 10% of the 88 million tonnes of food waste generated each year in the European Union (EU) is associated with date marking. Apart from this, food waste in the UK contributes to approximately 36 million tones of greenhouse gas (GHG) emissions annually. On a global scale, food waste accounts for about 8% of the total GHG emissions. Addressing food waste is crucial not only for reducing environmental impact but also for mitigating the broader effects of climate change. (Koks, 2021).

D’Amato et al. (2023) surveyed how EU-style date coding (use-by and best-before) affects consumers’ judgment of perishable food around the expiry date. It was found that the expiry dates significantly influence consumer assessment, while differences in the type of date codes have limited practical significance. Educating consumers about the significance of various date codes decreases their willingness to pay for potentially unsafe food. However, such education does not lead to an increase in willingness to pay for items with longer durability. Similarly, Patra et al. (2022) concluded a survey and found that a majority of stakeholders experience confusion regarding date coding, linking it to concerns about food safety and expressing hesitancy to consume foods beyond the mentioned date. Stakeholders believe that fostering a better understanding of the scientific basis behind date codes and leveraging modern technologies like mobile phone apps, social media, targeted community outreach education, and printed materials could be instrumental in reducing food waste. In another study, the impact of date code and freshness labeling on a consumer rejection of expired foods was studied in terms of use-by or best-before dating (Samotyja and Sielicka-Różyńska, 2020). Results indicated that the type of date code (best-before vs. use-by), freshness labeling, and food category play a significant role in influencing consumer decisions to reject food products. The criteria for rejection also changed as the product approached or exceeded its expiration date.

| 5. Current status of date codes (best-before dates) | ▴Top |

Nowadays, grocery stores are taking steps to reduce customer confusion associated with date labels. For instance, Aldi UK recently announced the elimination of best-before dates from approximately 60 of its fresh vegetable and fruit products. Numerous other UK and European supermarkets/producers have already adopted similar initiatives or are planning to do so. The aim is to minimize food waste by encouraging consumers to rely on their own judgment in determining the edibility of products, reducing the necessity to strictly adhere to date codes. For instance, Morrisons, a UK supermarket, encourages customers to use the “sniff test” to assess the drinkability of its cow’s milk (Mullen, 2023). Similarly, Asda Stores Limited confirmed eliminating best-before dates from the packaging of nearly 250 fresh vegetable and fruit products in its UK stores. Instead, these dates will be replaced with a display code that is internally used by employees to assess the freshness of the products. This move aims to simplify date information for consumers and provide them with an alternative indicator of freshness (The Guardian, 2022). Likewise, Canada is considering the possibility of removing/amending best-before dates on food products as a measure to tackle the issue of food waste (Waberi, 2023). In addition, Unilever is introducing a new packaging label positioned directly following the “best-before” code on specific food products: “often good after.” This initiative, created in partnership with Too Good To Go and industry stakeholders, is designed to decrease food waste at the consumer level (Southey, 2019). In 2019, FDA issued a letter encouraging the food industry to embrace a unified and standardized “best-if-used-by” label for products that remain safe to consume even if their smell or taste has diminished (Deighton, 2022).

Certain supermarkets are exploring the implementation of smart shelves, wherein the prices of items are adjusted in accordance with decreasing “use-by” and “best-before” dates. This technology holds the potential to extend into households, with smart fridges having the capability to alert consumers about approaching “use-by” dates (Koks, 2021). Interestingly, two business partners based in Sheffield, UK, have transformed the concept of using “out-of-date food” into a thriving business. Through their company, Approved Food, they purchase substantial quantities of surplus food stocks from wholesalers and supermarkets. This food, often either short-dated or past its best-before date, is then resold to their customers, which not only mitigates food losses and waste but also proves advantageous for the consumer.

| 6. Alternatives to date codes | ▴Top |

Eliminating date codes necessitates the adoption of alternative methods to preserve the freshness of food and ensure safety. Those approaches would impede the autolytic process, which involves the degradation or ripening of the product and inactivate spoilage microbes. In response to the significant issue of food waste, technological initiatives have focused on creating innovative solutions to empower consumers in making better-informed decisions, leading to a reduction in food wastage. Recent advancements, for example, involve the emergence of smart packaging methods, including intelligent packaging, active packaging, snap-packs, modified atmosphere packaging (MAP), and resealable packaging, designed to prolong the shelf life of products and assist consumers in monitoring the freshness and quality of products. For instance, active and intelligent packaging, which incorporates active ingredients and sensors/indicators to maintain the quality of food and track its condition throughout the life cycle. Additionally, there are smart labels affixed to packages that inform consumers about the freshness of the food, providing a means to ascertain its current quality. Barone and Aschemann-Witzel (2022) reported that consumers predominantly rely on either the expiry date or their own senses when evaluating food freshness. Trust in the accuracy of product labels emerges as a crucial factor influencing the integration of smart labels into food handling practices. The results suggest that in-store demonstrations and informative content would enhance and encourage the adoption of smart labels. Besides, snap-packs are comprised of individual portions tailored for single-person consumption, and they are further packaged in larger quantities. Consumers have the flexibility to open only the desired amount of the product while the remaining portions remain securely sealed in the packaging. Although a straightforward concept, it has already demonstrated its effectiveness in minimizing waste. In contrast, MAP involves sealing food along with specific concentrations of carbon dioxide, oxygen, and nitrogen. This distinctive blend of gases, adjusted based on the specific type of fresh food being packaged, serves to preserve the color and taste of the food while also extending the shelf life. Additionally, the application of resealable packaging goes a step further in extending the shelf life of a product once it has been opened. The air-tight seal plays a crucial role in preserving freshness, preventing the product from becoming stale, and instilling confidence in consumers to use the food over an extended period.

Apart from this, technologies such as high-pressure processing (HPP), ionizing radiation, quick response (QR) code, and clean flow can be potential alternatives to maintain the overall quality and extend the shelf life of food. HPP is a non-thermal preservation method that has the capability to deactivate vegetative microorganisms, such as yeast and mold, in food while also inducing alterations in certain characteristics of the food. Furthermore, HPP could control enzymatic reactions (e.g., polyphenol oxidase and peroxidase), which are associated with the enzymatic degradation of active compounds (e.g., anthocyanins), leading to the occurrence of browning (Hossain et al., 2022a, 2022b). On the other hand, a clean flow device utilizes a forced-air ozone reactor and serves as a chemical-free and waterless sanitizer for produce. This innovative system aims to decrease health risks and enhance the shelf life of the treated items. Aside from this, a recent study found that consumers express a willingness to endorse QR codes as a means to gain a better understanding of the safety duration of milk. The researchers suggest that this approach could eliminate the necessity for printed “use-by”/”best-by” dates on milk packages, potentially reducing food waste by implementing more precise and helpful scanning technologies (Poole, 2022). In addition, Fallah et al. (2023) suggested that ionizing radiation and biobased active packaging can be promising ways to maintain the overall quality of muscle foods.

| 7. Smart packaging | ▴Top |

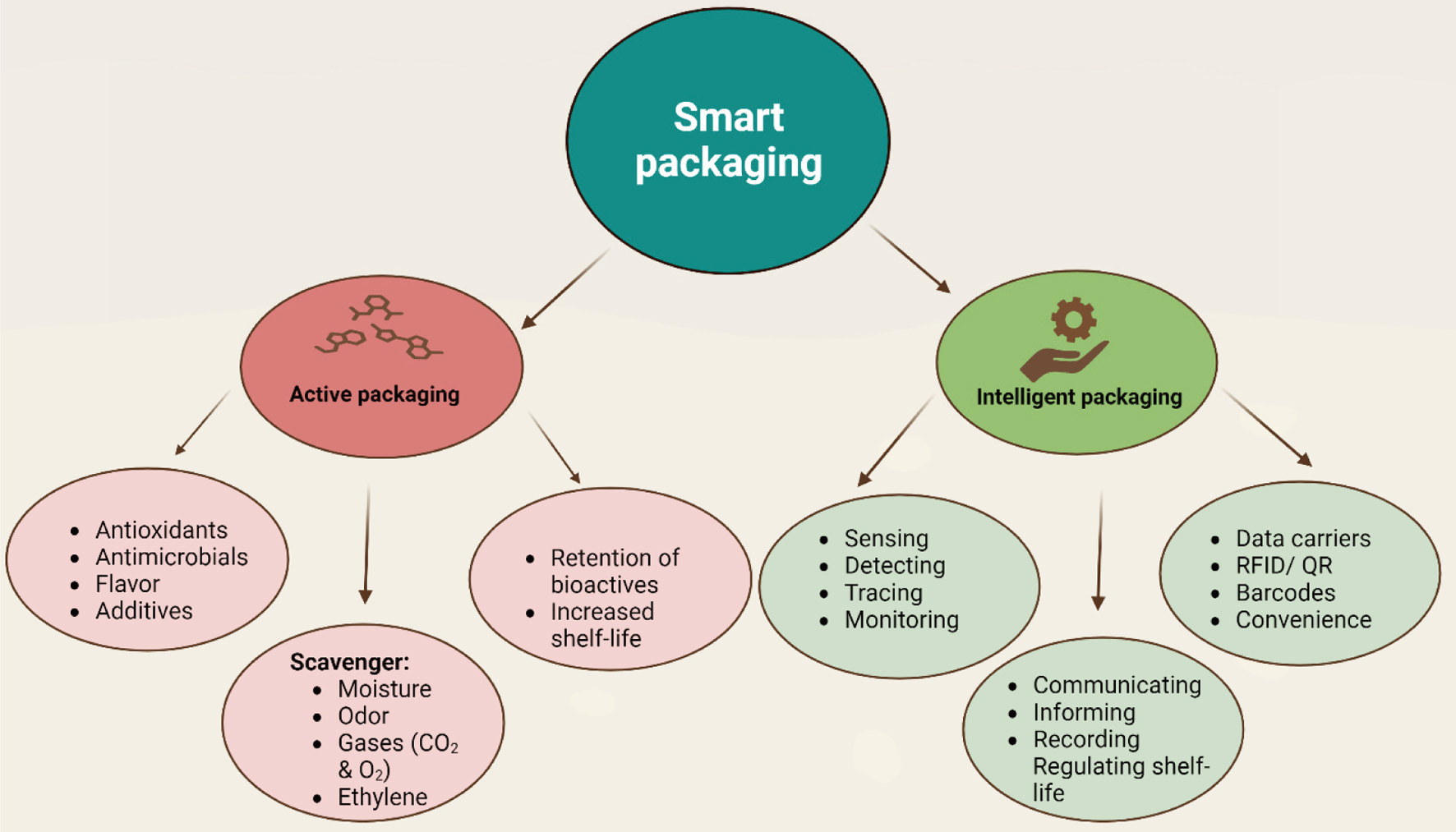

In the current market, there is a growing demand from consumers for organic foods and products with cleaner additive labels. The trend towards preservative-free options is a significant factor compelling the industry to address the impact of product oxidation within the packaging itself (e.g., smart packaging), rather than relying on additives in the food or increased packaging. A smart packaging material employs biodegradable materials such as proteins, polysaccharides, lipids, and other naturally derived biopolymers, along with various natural antimicrobials and antioxidants, including phenolic compounds (Shahidi and Hossein, 2023). This innovative packaging serves to protect food by preventing harmful bacteria and spoilage microorganisms and also contributes to environmental sustainability by eliminating plastic waste. Smart packaging represents a comprehensive system that integrates active, intelligent, and connected packaging to observe both internal and external changes in food products (Figure 1). It reacts to these changes by communicating with an external surface, creating a straightforward yet extensive solution for monitoring and responding to variations in the food environment (Ganeson et al., 2023).

Click for large image | Figure 1. Overview of smart packaging. |

Active packaging utilizes technology that deliberately releases or absorbs compounds from the food or the headspace of food packaging. This approach effectively prolongs the shelf life of products by controlling microbial growth, lipid oxidation, and moisture loss, outperforming traditional food packaging methods. Active packaging, biodegradable materials, and essential oils are crafted using diverse extracts sourced from plants and food. To mitigate spoilage and extend shelf life, manufacturers are incorporating materials such as copper-based low-density polyethylene (LDPE) films and packaging made from biopolymers. Furthermore, active packaging methods aim to decrease reliance on traditional plastic by incorporating biodegradable edible layers that possess effective oxygen and grease barrier properties. This dual approach not only enhances preservation but also addresses environmental concerns associated with plastic waste (Ahmed et al., 2022; Shahidi and Hossain, 2022a). Usually, active packaging can be categorized into two main types: non-migratory active packaging, involving scavengers designed to eliminate undesirable components from the packaging environment without intentional migration; and active releasing packaging, which focuses on emitters facilitating controlled migration of desired substances into the packaging environment, positively influencing the food product. The majority of non-migratory active packaging systems within a food product function as moisture scavengers, oxygen scavengers, and ethylene absorbers. In contrast, active release packaging systems encompass antimicrobial packaging, carbon dioxide emitters, and antioxidant packaging (Ahmed et al., 2022; Ahari and Soufiani, 2021).

Intelligent packaging is an efficient system for implementing intelligent enhancements in monitoring, tracing, documenting, and communicating, thereby providing information, facilitating consumer safety, and aiding decision-making. Freshness indicators, as intelligent devices, enable the monitoring of food quality throughout transportation and storage. For instance, freshness indicators integrated into intelligent packaging have the capability to assess food freshness by sensing alterations in temperature, pH, moisture, or the presence of specific microbiological metabolites or chemicals associated with food spoilage, including biogenic amines, volatile nitrogen compounds, carbon dioxide, organic acids, and sulfuric compounds. These indicators provide real-time freshness predictions and alert consumers to dispose of spoiled food items through visible color changes or signals that can be recognized using portable digital devices. They also signal the impact of selective pathogens on perishable food items. Utilizing an electrospinning device, biodegradable biopolymers are transformed into a nanoscale mesh of antimicrobial fibers. These fibers are specifically programmed to detect and repel harmful bacteria and spoilage microorganisms, ensuring the freshness and safety of the enclosed food items (Ganeson et al., 2023; Yu et al., 2023).

7.1. Can smart packaging eliminate the date codes (best-before dates)?

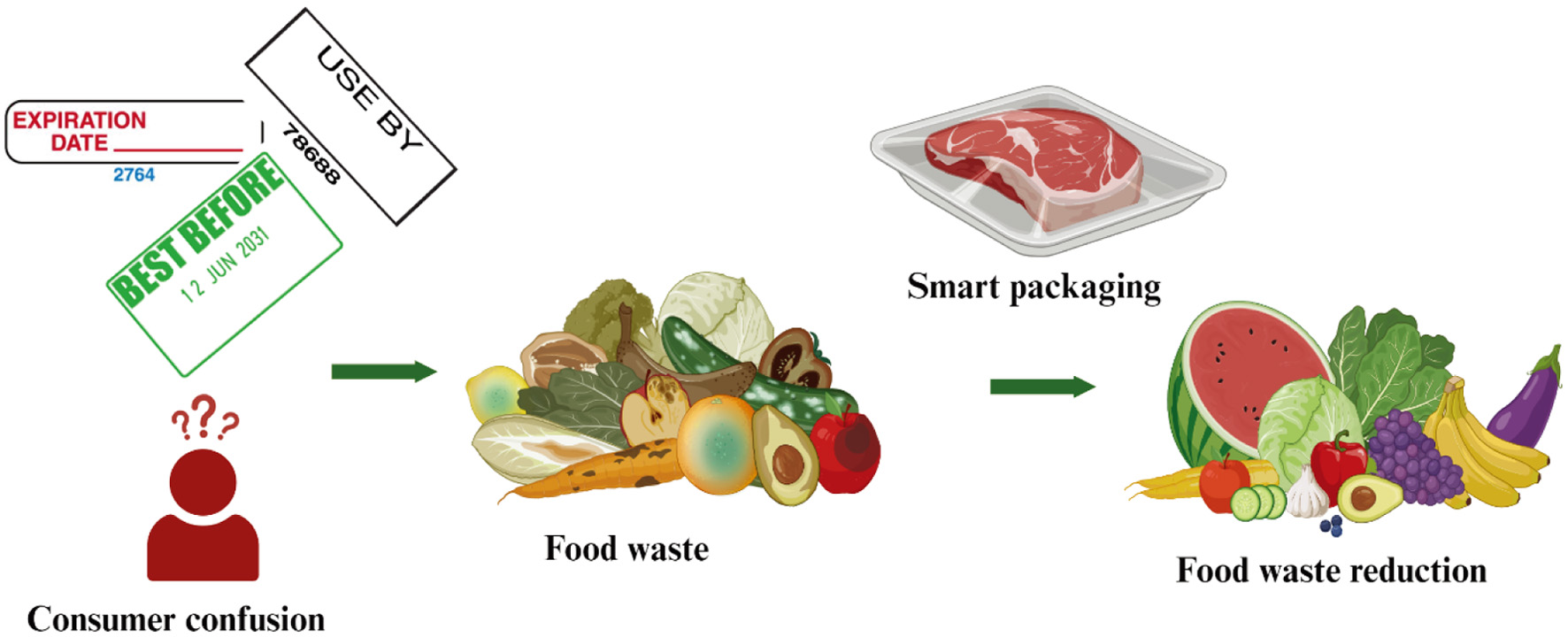

The objective of smart packaging is to enhance the safety of food products and mitigate food waste resulting from misunderstandings related to product date labels. For instance, date codes like best-before, best-if-used-by, sell-by, use-by, prepared-on, manufactured-on, freeze-by, and expire-on dates often lead consumers to mistakenly discard food items that have surpassed their peak quality but are still safe for consumption. Therefore, smart packaging could be a promising way to tackle this problem as it enables traceability, serving as a crucial component for predicting food demand (Figure 2). This capability helps prevent overproduction and wastage by providing valuable insights into the movement and consumption patterns of food products. Smart packaging commonly incorporates technologies like radio-frequency identification (RFID), QR codes, and near field communication (NFC), offering several advantages. Smart packaging provides real-time tracking and tracing of a product’s exact location throughout the supply chain. This is achieved through unique code management, offering visibility into the product’s life cycle. Moreover, it enables the analysis and control of the environment outside or inside the package by controlling volatile compounds movement, gas transfer, microbial growth, moisture, and oxidation due to the presence of active ingredients. This information informs the product’s retailer, manufacturer, or consumer about its current condition, empowering companies to take proactive steps in preservation. In addition, smart packaging enhances brand transparency through data and analytics. By engaging consumers with information, it contributes to building trust and reputation. This transparency is achieved through real-time insights into the product’s journey and condition, fostering consumer confidence. Further, connected packaging facilitates direct communication between the brand and the consumer through the internet and smartphones, offering access to product information. The primary activation points in connected packaging are NFC chips and QR codes, and their applications vary based on the product type, industry, and specific use cases. For example, Innoscentia, a Swedish manufacturer specializing in dynamic sensor labels, is in the process of creating printed intelligent expiry codes. These codes are designed to substantially decrease food wastage by allowing real-time monitoring of food quality (FutureBridge, 2022; Ganeson et al., 2023; Roeder, 2022).

Click for large image | Figure 2. Food waste due to consumer confusion arises from various date labeling. |

The oxidation of food materials is the second-largest contributor to food spoilage, surpassed only by microbial degradation, constituting approximately 25% of postharvest and post-slaughter food spoilage. Researchers have investigated various antimicrobial active packaging approaches to address this issue. These methods include blending antimicrobials into the packaging material, the use of sachets, internally filming/coating packaging materials, or generating volatile antimicrobials within the package. Numerous antimicrobial compounds have been explored in this context, such as parabens, organic/phenolic acids, natural antimicrobial polymers, metals, fungicides, antimicrobial proteins and enzymes, essential oils, and plant extracts. The shared objective is to delay or reduce the growth of spoilage microbes, thereby enhancing the shelf life of food products (Hossain et al., 2023; Shahidi and Hossain, 2022b; Senadheera et al., 2023). Therefore, by prolonging the shelf life, preserving bioactive compounds, and maintaining the overall quality of products with smart packaging, food waste can be reduced, which ultimately helps to eliminate or supplement date codes. This is because most consumers dispose of food primarily due to their perception that it has spoiled or lost its taste and freshness. The date codes and labels on food items offer information to consumers that influence their decisions regarding whether to consume or discard the product (Weis et al., 2021). Thus, smart packaging has the potential to supplement date labels and assist consumers in minimizing their waste. Nonetheless, this should be implemented up to a certain point without compromising any food safety issues.

| 8. Challenges and future perspectives | ▴Top |

The future appears promising for the smart (active and intelligent) packaging sector. With the added benefits of minimizing food waste and ensuring food wholesomeness and safety, smart packaging is poised to play a substantial role in digitizing the food supply chain. However, to achieve economies of scale in this domain, the industry must surmount significant challenges, including the complexity of integrating smart devices into existing packaging systems, the high costs associated with mass production, and concerns related to sustainability, security, and data privacy. The adoption of blockchain in packaging, along with the implementation of advanced technologies, is expected to offer solutions to these challenges. Nevertheless, this innovative packaging technology presents substantial financial benefits, making it economically more valuable. The capability of smart packaging technology to diminish counterfeiting can lead to cost savings, provide transparency in product traceability throughout the production and distribution chain, enhance the speed and precision of just-in-time inventory and delivery processes, and support marketing efforts by fostering increased engagement with customers. Additionally, it contributes to making food products last longer, appear visually appealing, and taste better, thereby reducing costs and improving overall profitability. Therefore, food packaging, particularly smart packaging, plays a pivotal role in minimizing food waste. When appropriately considered and implemented, it has the potential to bring about the transformative change needed to address food waste challenges as well as supplement or even eliminate date labels. In particular, one potential consideration is the extension of “best-before” dates for certain durable foods, which could significantly reduce food wastage. However, it is important to note that eliminating “best-before” dates would require the adoption of alternative methods to ensure food safety and quality, and smart packaging might tackle the problem. In addition, to minimize food waste in households, it would be beneficial to focus on raising public awareness about food labeling and safety. A 2022 CBC News reported that 32% of Canadians expressed strong opposition to the removal of date labels (Benchetrit, 2022). Therefore, addressing consumer confusion regarding product dates and increasing awareness of date coding are crucial factors that need to be considered and that requires educating the consumers by employing all means available.

Acknowledgments

Financial support from Natural Science and Engineering Research Council (NSERC) of Canada (RGPIN-2016-04468) is acknowledged.

| References | ▴Top |